Insulating flat roofs: compact roof and warm compact roof

Does your new build, extension, rooftop addition or renovation have a flat roof? Do you highly value acoustic comfort? Is the available building height limited? Is cost an important factor? Or do you prefer working with sustainable materials?

Then be sure to consider this solution as an alternative to the conventional warm roof or inverted roof.

Our solution is also suitable for flat roofs with solar panels or terraces, as well as for green roofs.

The text on this page was automatically translated. Minor translation errors are possible. In case of doubt, the original versions (Dutch and French) are correct.

Download(s)

What does our insulation system ‘Compact Roof’ consist of?

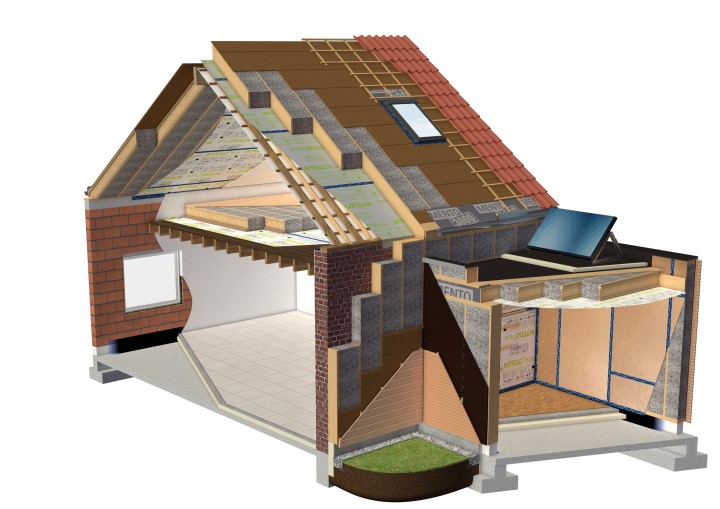

Flat roofs are increasingly built with a load-bearing wooden structure. For this type of build-up, it is ideal to insulate according to the principles of the compact roof system.

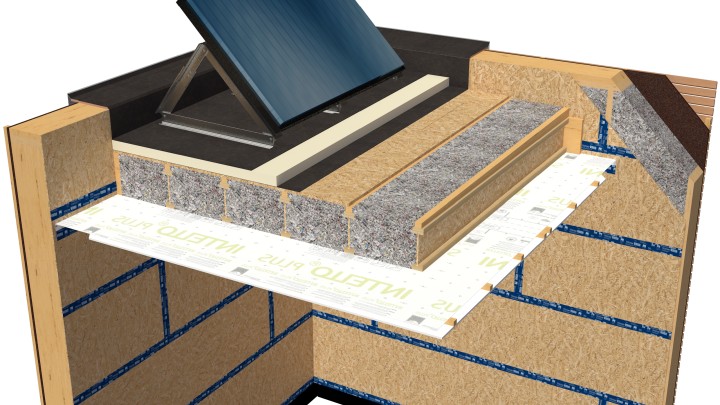

This system consists, from outside to inside, of the following layers:

- the waterproofing layer;

- the roof deck, usually made of construction boards (OSB, plywood, fibre cement, etc.) or solid planks;

- the wooden joists, with the space between them fully filled, preferably with iQ3 cellulose insulation;

- a humidity-variable pro clima INTELLO (PLUS) vapour control layer, installed underneath the joists and supported by cross battens;

- a vapour-open interior finish.

Using a humidity-variable vapour control layer and a vapour-open insulation material like iQ3 cellulose — completely filling the space between the vapour barrier and the roof deck without a (ventilated) air gap — is essential for achieving a durable result with good moisture management.

Products used

- iQ3 cellulose insulation

- pro clima INTELLO PLUS

Strong, humidity-variable and airtight vapour control layer for all fibrous insulation materials

Variant: warm compact roof

Is your flat roof (partially) shaded? Or are you planning to install solar panels, a terrace, or a green roof on top of it? Then the warm compact roof variant (formerly called duo roof) is the recommended method.

With the warm compact roof, you add two extra layers to the compact roof system: a vapour barrier (with a μd-value ≥ 100 m) placed directly on top of the roof deck, and an additional insulation layer above that. This increases hygric safety (see ‘important note’ below) while still allowing you to benefit from the advantages of the compact roof principle.

The amount of insulation to be added above the roof deck depends on several factors, such as the interior climate, exterior conditions, insulation thickness below the roof deck, and so on.

At ISOPROC, we have created a clear table showing the minimum additional insulation required for several standard situations. You can find this table in the document available for download at the bottom of this page.

What are the advantages of this flat roof insulation system?

The compact roof offers several advantages compared to other roof types, particularly the conventional warm flat roof (the most common type of flat roof).

- A compact roof is often by far the most cost-effective flat roof solution. For example, during renovations, there’s usually no need to raise roof upstands, and existing drains can often be maintained. On smaller surfaces, such as extensions in city centres, dormer windows, etc., the compact roof is often the most efficient solution.

- By placing the insulation within the available wooden load-bearing structure, you limit the total roof height even with large insulation thicknesses, resulting in significant cost savings.

- The non-loadbearing insulation used underneath the roof deck in a compact roof is usually cheaper than the loadbearing insulation required above the deck in conventional flat roofs. Moreover, compact roofs typically use blown-in insulation such as iQ3 cellulose. This combines fast installation without cutting waste with a seamless, gap-free fill. Even in compartments with complex shapes, iQ3 cellulose insulation ensures smooth and complete coverage.

- Installing and securing the waterproofing layer is easiest on a continuous and solid surface. In a compact roof, the waterproofing is applied directly onto the roof deck, whereas in a warm roof it must be applied over the insulation layer.

- Unlike the warm roof, in a compact roof the vapour barrier and insulation are installed from the inside — and only after the waterproofing of the roof has been fully completed. This means there is no risk of rainwater getting into the insulation. You are not dependent on weather conditions and can work without time pressure.

- Unfortunately, it is quite common for the waterproofing not to be 100% watertight from the beginning, or for small leaks to develop later on, allowing occasional water ingress.

In warm roofs, minor leaks often go unnoticed because the vapour barrier beneath the insulation often acts as a second waterproofing layer. Even if leaks are eventually detected, it is usually difficult to locate them. While the underlying structure may remain protected from construction damage, the insulation may already be wet — possibly even from the construction phase. In contrast, with a compact roof, any leaks present from the start can be easily detected, located and repaired before the insulation and vapour barrier are installed. In the rare event of minor water infiltration later on, the roof can still dry inward, which is nearly impossible in a conventional warm flat roof.

Because the airtight layer of the roof (the vapour barrier) in a compact roof is located below the roof structure, it can easily be connected to the other airtightness layers on the inside of the exterior walls. Air leaks can be easily repaired. In a warm flat roof, where the vapour barrier is placed on top of the roof deck, this is often impossible.

The airtightness and the correct installation of the vapour barrier can be tested by putting the building under negative pressure (for example, with a BlowerDoor test).

For calculating environmental impact, it is best to base your analysis on TOTEM. TOTEM is a tool jointly developed by the three Belgian regions, allowing the total environmental impact of different build-ups to be compared objectively.*

We invite you to compare a compact roof using iQ3 cellulose and a humidity-variable vapour control layer pro clima INTELLO (PLUS) based on polyolefins, with a warm flat roof using high-density synthetic insulation or rock wool, installed on a vapour barrier.

* In addition to energy consumption over a service life of 60 years, TOTEM also takes into account the overall impact (CO₂ and nitrogen emissions, water and raw material consumption, ozone impact, and a wide range of other factors) of the materials used, from the extraction of raw materials to the demolition of the building.

We have documented this advantageous flat roof insulation solution in a comprehensive file. It contains essential information about the system’s operation, the rules, and the guidelines for increasing hygric safety. We also included connection details and drawings for cavity walls combined with compact roofs with eaves, timber frame constructions with compact roofs, timber frame constructions with warm compact roofs, and renovation solutions.

Download the complete solution for compact roofs and warm compact roofs below.

Still have questions? Don’t hesitate to contact our free technical helpdesk. We are happy to share our expertise and in-depth knowledge.

Important note: why are a humidity-variable vapour control layer, vapour-open insulation and meticulous installation essential for flat roofs?

Building structures that never get wet is ideal. But how realistic is that? The risk of moisture entering the build-up — often already during the construction phase, or later through convection, diffusion or infiltration — is significant. It is therefore safer to design structures that, if they do get wet, can dry out effectively.

Flat roofs are always finished on the outside with a waterproofing layer that is highly vapour-retardant (with a μd-value ranging from at least 15 metres to several hundred metres). As a result, any moisture present inside the roof build-up can barely dry out to the exterior. This is different from pitched roofs, where a vapour-open underroof can be used.

The only remaining drying path for flat roofs is towards the inside. This can be achieved by installing a humidity-variable vapour control layer on the interior side. How this works, and the key points and conditions you need to respect, are explained in the downloadable document below.

Online opleiding

Bekijk hieronder het opgenomen webinar.

Heb je liever een opleiding/webinar waarbij je interactief kan overleggen met onze specialist?

Schrijf je dan in op één van de opleidingen (zie onderaan).