Insulating a pitched roof with a load-bearing ridge beam and rafter boards

Are you working on a new-build project or a major renovation of your pitched roof? Looking for an efficient, high-quality, and sustainable way to insulate your roof from the inside? Is cost an important factor?

Then be sure to consider this solution as an alternative to the conventional trussed roof.

The text on this page was automatically translated. Minor translation errors are possible. In case of doubt, the original versions (Dutch and French) are correct.

Download(s)

What does our insulation system 'Pitched roof with load-bearing ridge beam and rafter boards' consist of?

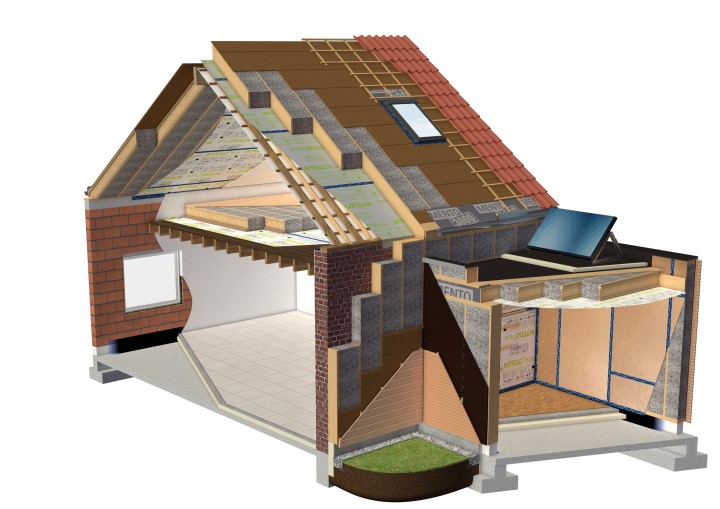

The design of this type of sloped roof is simple yet effective. A solid or glulam ridge beam at the top of the roof is dimensioned to minimize deflection. It supports solid timber rafter boards (or I-beams) that run diagonally and continuously from the eaves to the ridge beam, without the need for additional intermediate support. The spacing between these rafter boards (or I-beams) is typically around 60 cm. Their width and thickness depend on the span and the desired insulation depth.

On the exterior side, a Celit 4D sarking board is applied. On the interior side, the system includes a pro clima INTELLO PLUS smart vapour control layer. Between the rafters, locally produced iQ3 cellulose insulation is blown in.

Products used

- Celit 4D

Premium sarking and wall protection board made from sustainable wood fibre - iQ3 cellulose-insulation

- pro clima INTELLO PLUS

Robust, moisture-variable and airtight vapour control layer suitable for all fibrous insulation materials

Smart design: efficiently absorbs thrust forces

By using an exceptionally rigid ridge beam with minimal deflection, so-called thrust forces are effectively prevented. These are lateral forces that would otherwise occur if the ridge were to sag under the roof’s weight, pushing outward on the supporting structure and exerting pressure on the exterior walls. A stiff ridge beam absorbs these loads and keeps the structure stable.

In contrast, a conventional (whether prefabricated or not) trussed roof system requires additional horizontal ties and vertical supports to resist these forces.

What are the advantages of this roof system?

Because the solution with a load-bearing ridge beam and rafter boards requires NO horizontal ties or vertical supports, the entire roof space can be used without obstruction. This also simplifies the installation of insulation and airtightness layers. In addition, sustainable materials such as Celit 4D and iQ3 cellulose insulation contribute to a highly comfortable indoor climate and offer maximum protection against moisture and structural damage. As a result, your investment remains valuable in the long term.

- This roof build-up allows for exceptionally efficient insulation with minimal complexity. When using our solution with 225 mm high rafter boards, you can achieve an R-value of approximately 5.9 m²K/W.

- Unlike many other roof systems (e.g. those using sandwich panels), our approach also offers excellent acoustic insulation. As part of a research project on roof insulation near airports, aiming for a 40 dB reduction in low-frequency noise, this build-up outperformed the target by an additional 5 dB.

- Energy savings and indoor comfort are heavily dependent on airtightness. In conventional trussed roofs, airtight installation is both labour-intensive and costly, due to the many horizontal and vertical structural elements that puncture the airtight layer. In contrast, a roof with a load-bearing ridge beam enables a continuous and easily installed airtight layer.

- The combination of a Celit 4D sarking board and iQ3 cellulose insulation, complemented by external shading and a suitable ventilation system, offers effective protection not only against winter cold, but also against summer overheating.

Savings start at the design phase

Save on material costs

With a pitched roof using a load-bearing ridge beam and rafter boards, material savings are built into the system. There’s no need for horizontal ties or vertical supports. Additionally, iQ3 cellulose insulation completely fills the available space between the rafters, with no cutting waste or gaps. This makes the construction more cost-effective than a traditional setup using mineral wool and underlay foil. Naturally, the system is also eligible for insulation and renovation subsidies.

Save time on installation

Pre-cut, pre-marked and pre-drilled rafter boards are lightweight and easy to handle, often by just one person. With proper preparation, the timber frame of the roof can be assembled within a few hours. The Celit sarking board on the exterior side is also quick and straightforward to install.

Not only is the air barrier on the interior side much easier to apply compared to a trussed roof, the blown-in iQ3 cellulose insulation can be installed quickly and efficiently: there’s no need to carry up and manually cut insulation packs. Anyone who’s ever tried to install insulation batts, with a perfect fit across the entire width and depth, especially around ridges, wall plates, valleys and hip rafters, knows how time-consuming and error-prone that process can be.

A Celit 4D sarking board not only adds an extra layer of insulation but is also significantly more robust than a standard underlay membrane.

By combining Celit 4D, iQ3 cellulose insulation, and the pro clima INTELLO PLUS smart vapour control layer, the risk of structural damage (e.g. wood rot) and harmful mould caused by moisture is reduced to an absolute minimum. Moisture transport within the construction is optimally managed thanks to the integration of the three most effective strategies for preventing building damage:

- Moisture ingress from the interior is blocked by excellent airtightness and the vapour-retarding function of the pro clima INTELLO membrane.

- Drying potential is maximised. Any residual moisture within the structure can evaporate outward through the Celit 4D sarking board, or, depending on humidity conditions, toward the interior via the moisture-variable INTELLO membrane.

- Moisture buffering: both Celit 4D and iQ3 cellulose insulation are capable of temporarily absorbing small amounts of moisture and releasing it later as conditions allow.

In addition, insect infestation is effectively prevented. Celit 4D on the outside and the INTELLO membrane on the inside create a physical barrier, making wood inaccessible. And even if an insect is already present in the timber, it won’t be able to leave or reproduce due to the full cavity fill with iQ3 insulation, effectively halting any life cycle. This makes it possible, in most cases, to build using untreated wood.

Because there are no ties or supports (as mentioned earlier), the space beneath the roof remains completely open and flexible. You're not limited by horizontal or vertical timber elements obstructing your layout, giving you full freedom to design and use the space as you wish.

To assess environmental performance, we rely on an analysis using TOTEM. TOTEM is a tool jointly developed by the three Belgian regions that allows for objective comparison of the total environmental impact of building assemblies.*

Step by step, we move from a conventional roof structure with standard insulation levels to a more sustainable alternative.

- As a baseline, we consider a roof with 175 mm rafter boards, a standard underlay membrane on the exterior, and mineral wool insulation (U-value = 0.25 W/m²·K).

- Replacing the membrane with a Celit 4D insulating sarking board (U-value = 0.22 W/m²·K) reduces the total environmental impact by 3 percent.

- If the mineral wool is then replaced with iQ3 cellulose insulation, the improvement increases to 11 percent.

- Finally, by increasing the rafter height and cellulose insulation to 300 mm (U-value = 0.13 W/m²·K), the environmental impact is reduced by up to 38 percent (analysis: April 2024).

* In addition to energy consumption over a 60-year lifespan, TOTEM also evaluates the overall impact of materials used. This includes CO₂ and nitrogen emissions, water and resource consumption, ozone impact, and many other factors, from raw material extraction to end-of-life.

We have documented this cost-effective roof insulation solution in a detailed guide. It includes practical information on the installation of the timber structure, airtight layer, and wind and rain protection. You will also find construction drawings and descriptions of key connection points such as the ridge, eaves, and wall junctions.

You can download the complete solution for pitched roofs with a load-bearing ridge beam and rafter boards below.

Still have questions? Feel free to contact our free technical helpdesk. We are happy to share our expertise and practical know-how.

Still have questions? Feel free to contact our free technical helpdesk. We are happy to share our expertise and practical know-how.